Has anyone made any bracket to mount a bus pirate to a 2020 extrusion? I could whip up one, but wanted to check first in case anyone has already done it. I’m currently using a big blob of tacky tack to hold it in place, but it isn’t very secure.

I had to look up what that is, but yeah, that would be cool ![]()

You had to look up 2020 or tacky tack? ![]()

2020 ![]() I am not a mechanical person, and I was really late to the 3D printer game.

I am not a mechanical person, and I was really late to the 3D printer game.

As the latest cases have screw inserts maybe could drill out so a bolt can pass all way through and attach a flanged washer to hook on extrusion?

I was actually thinking the exact same thing recently, only I was wondering if the case would need a change to allow the pass-through. I understand that the screw inserts are manually added at the factory … maybe a few can be made without the inserts added?

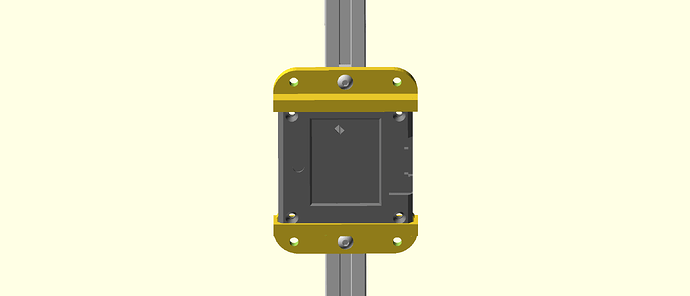

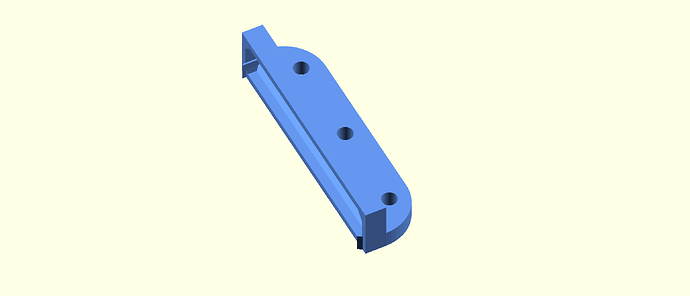

I was thinking of something simpler, like this…

My printer is offline for a few days, I’ll print these out sometime this week and confirm they work. If successful, I’ll post the file online.

Id be glad to pront a sample and provide feedback and photos. I have 2 printers available. Otherwise, ill await the results. Looks good though!

Looking good!

Will it fit both the old and new enclosure?

I haven’t kept up with the new enclosure. It would be best to make it fit both ones. Is there an openscad file for the new one?

It was modified by the factory. I’ll post the step or stl if I can find it.

There are two functional differences that would effect the bracket:

- The corners are now rounded

- There are (optional) 1.5mm silicone feet in the four corners

yeah, a step file would help. The bracket I made was pretty simple, I took the scad file and used it with hull() to hog out a hole so there’s a little clearance (like 1 mm). I can make the hogged out cavity such that it can take either one. Like the silicon feet you mentioned, there can be a slot to clear them.

2024 NOV 9 BP new enclosure SLA.zip (412.9 KB)

@ian , other than those changes, the injection molded case has the same basic outer dimensions (or “envelope”)? I presume the PCB assembly doesn’t change to accommodate the new case?

The sides’s profile was beveled on both top and bottom on the SLA(?) cases that I have. Does the new case carry on this same beveling?

If I don’t get my printer running by Wednesday I’ll send you the candidate file for you to test.

-Chris

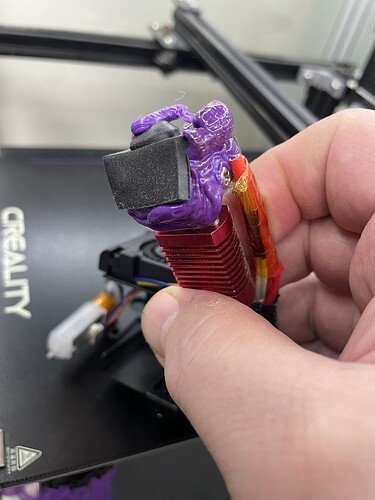

Here’s the small mishap that grounded my printer recently. I could probably salvage this one, but instead I now am the owner of a brand new so-called direct drive hot end for my almost-bottom -of-the-line cheap Chinese 3D printer (Creality Ender 5 pro). The new hot end came as a box of loose parts, so “some assembly required” as they say.

Wow that’s a proper mess! How did that happen?!?

I have a prussa mini+. It wasn’t the cheapest but was less than my “disposable Chinese tool” (laser cutter, CNC mill, reflow oven, etc) budget of $400usd.

I about blew a gasket getting the Z axis dialed in right. Eventually I got a set of sparkplug gap shims to measure the nozzle height and then it was smooth.

I get it out a few times a year and it just goes. The biggest issue is filament absorbing water over time. I staple silica kitty litter into a few layer of coffee filters and put two in the bag with every reel. That can keep it fresh for 12 to 36 months.

Like you, once I zeroed it in, it ran reliably whenever I fired it up. Unlike you, I completely ignored moisture effects on my filament. That may be a contributing factor to my “crash”. I will order a couple of new spools today, and I also have like 10 unopened spools I can use in the meantime. Mostly I want to replace the black-colored supposedly ESD-safe spool of filament for use with PCB assemblies.

I also hated the bed leveling, Z-axis process. I think I have that under control with the BL Touch accessory, knock on wood.

I started out with a Maker Farm i3v that I built, then I got an Anet A8, and from there I got a Tevo Tornado 300*300 * 400mm (The green one). I gave the Maker Farm away, but I still have the Anet (somwhere…), and the Tevo Tornado on my workbench. I haven’t printed anything in over a year though. The Tevo developed a bad habit of not being able to print small vertical pieces - It’s likely an issue with temperatures, and possibly using cheap filament.

I have a BL Touch for the Tevo, but I still break out the feeler gauges and level it myself - I guess I’m a glutton for punishment!

If anyone needs parts, I have a new authentic BL touch, thermocouples, extruders, nozles, thermal boots and A LOT more.

I’m in the U.S., so IDK how much sense it would make to ship out of country unless you need a bunch of things, but i just wanted to offer for anyone who may run across your work of art.