dude! check out what i missed>

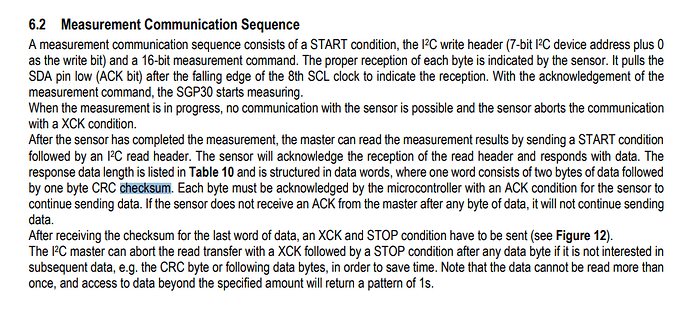

The sensor responds with 2 data bytes (MSB first) and 1 CRC byte for each of the two preprocessed

air quality signals in the order CO2eq (ppm) and TVOC (ppb). For the first 15s after the “sgp30_iaq_init” command the sensor is

in an initialization phase during which a “sgp30_measure_iaq” command returns fixed values of 400 ppm CO2eq and 0 ppb

TVOC.

so we cant send the sgp30_iaq_init before every measurement command, or it just resets the 15s of giving that static value. thats why we were seeing those same values over and over.

If i send the init and then wait

I2C> [0xB0 0x20 0x03 0x0E] D:1000

I2C START

TX: 0xB0 ACK 0x20 ACK 0x03 ACK 0x0E ACK

I2C STOP

Delay: 1000ms

I see the mA’s start to fluctuate but still get

I2C> [0xB0 0x20 0x08 0xE4] D:23 [0xB1 r:6]

I2C START

TX: 0xB0 ACK 0x20 ACK 0x08 ACK 0xE4 ACK

I2C STOP

Delay: 23ms

I2C START

TX: 0xB1 ACK

RX: 0x01 ACK 0x90 ACK 0x4C ACK 0x00 ACK 0x00 ACK 0x81 NACK

I2C STOP

which would be what the datasheet said about the 400ppm static value.

so

[relo@killengn sgp30]$ echo $(( (0x01 << 8) | 0x90 ))

400

and other is obviously 0. checksums are correct as well.

But then if i wait >15s check this out!

without alcohol swab near it

I2C> [0xB0 0x20 0x08 0xE4] D:23 [0xB1 r:6]

I2C START

TX: 0xB0 ACK 0x20 ACK 0x08 ACK 0xE4 ACK

I2C STOP

Delay: 23ms

I2C START

TX: 0xB1 ACK

RX: **0x01 ACK 0xCE ACK** 0x2D ACK 0x00 ACK 0x00 ACK 0x81 NACK

I2C STOP

which is

[relo@killengn sgp30]$ echo $(( (0x01 << 8) | 0xCE ))

462

^co2

and 0 for TVOC ( ACK 0x00 ACK 0x00 ACK 0x81 ) 0x81 being the CRC for 0x00.

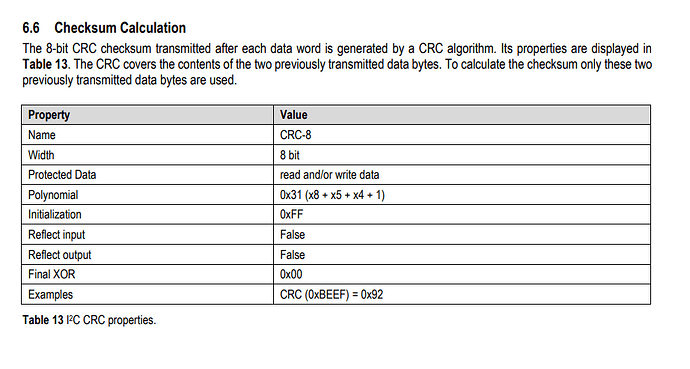

[relo@killengn sgp30]$ python3 sgp30_crc.py 0x00 0x81

–

now with soaked alcohol swabsuper close to the hot plate MOX sensor

I2C> [0xB0 0x20 0x08 0xE4] D:23 [0xB1 r:6]

I2C START

TX: 0xB0 ACK 0x20 ACK 0x08 ACK 0xE4 ACK

I2C STOP

Delay: 23ms

I2C START

TX: 0xB1 ACK

RX: 0xDF ACK 0xF2 ACK **0x3C ACK 0xEA ACK** 0x60 ACK 0xA2 NACK

I2C STOP

I2C>

which just so happens to be the friggin max reading for 60000ppb for the TVOC sensor

[relo@killengn sgp30]$ echo $(( (0xEA << 8) | 0x60 ))

60000

–

thank you so much. this was a great learning experience.

couple of bonus questions about buspirate cli i thought of when doing this

1.) is there a way to turn off verbosity of the transmission side, and only get the read? not super important but when running it tons of times when i might only want to show the command and what im trying to read, for copy and paste purposes.

2.) how can i print out values such as the mA. it shows it super pretty on the buspirate and in the CLI of course, but was just wondering if i could simply echo the current value of stuff

3.) can i do arithmetic and bitwise arithmetic in BP? like how i was using echo or printf in bash

thanks so much ian