This evening I did one measurement on my 7Rev0 I wanted to do:

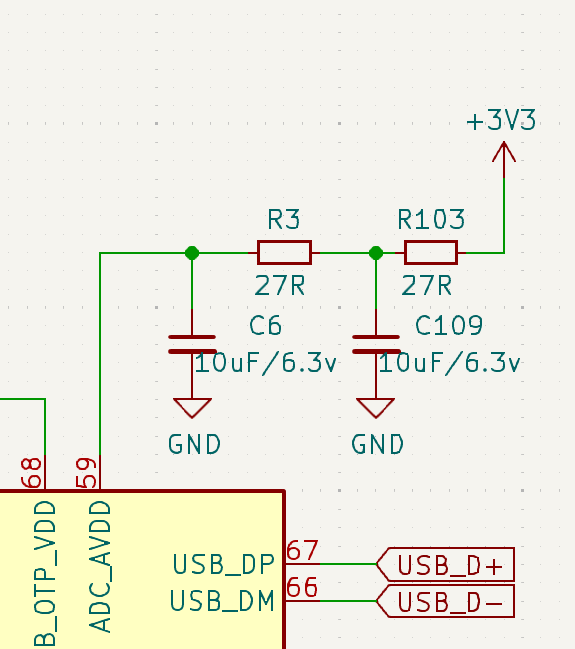

Measuring the filter for ADC_AVDD of the RP2350.

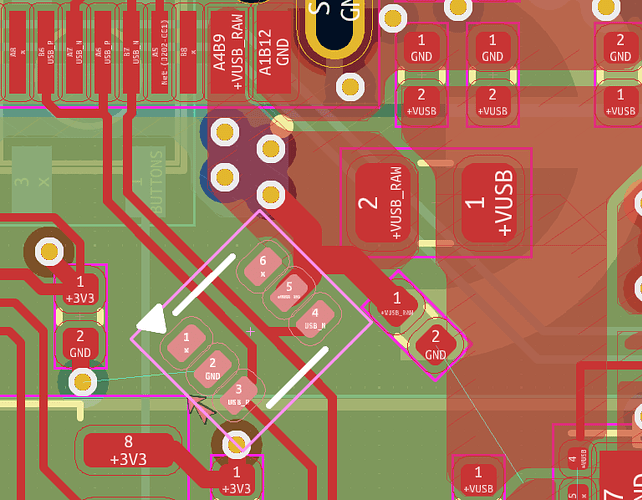

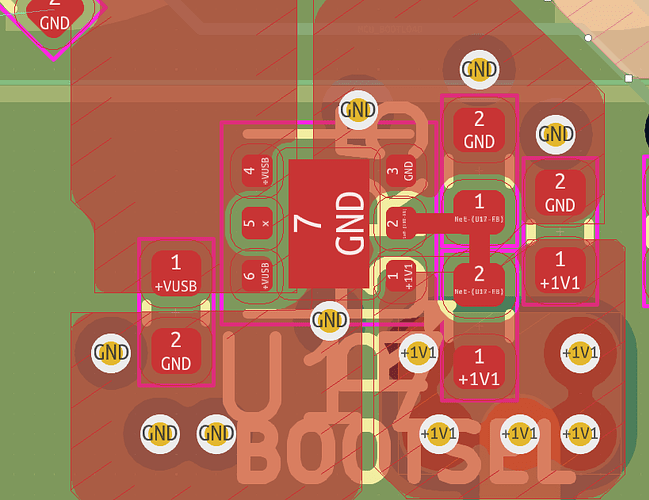

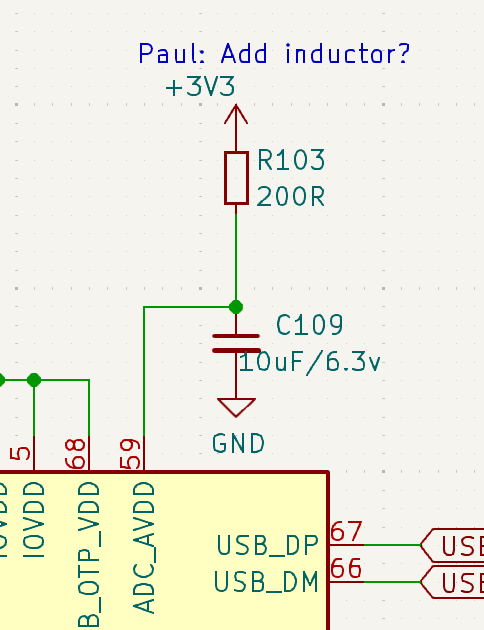

Current setup:

Measured voltages (with a warmed-up K 2001 no less):

3.3V rail: 3.3159V (0.48% off nominal)

AVDD in bootloader: 3.3158V

AVDD with regular BP firmware: 3.2891V

AVDD in scope mode: 3.2853V

→ Current drawn in scope mode: 153 µA

So the RP2350 clearly has a current draw on AVDD that changes with load, and the more ADC sampling you do, the more current is drawn. In scope mode we are 30.6 mV off, that is about 0.93%.

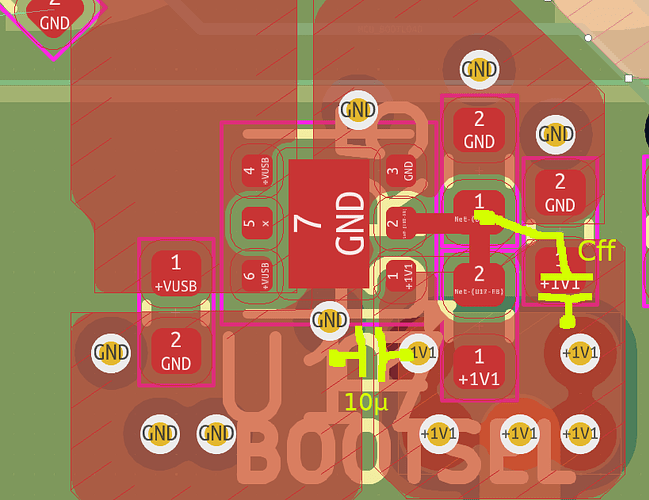

This is not deadly, but I think this is wasted accuracy and it can be mitigated easily by improving the filter like this:

The 27 Ohms are already used on the board, so no extra BOM line.

The 153 µA would now just cause a voltage drop of 8.3 mV, improving the inaccuracy caused from 0.93% to 0.25%.

How will the new filter affect noise on AVDD?

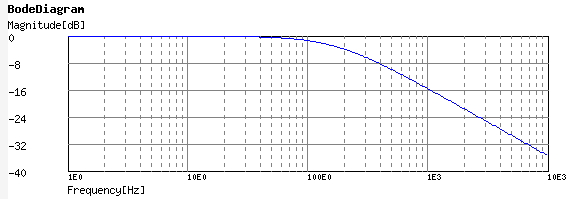

Let’s start with the filter as it was in Rev6 (as filtering there was most probably ok): Single order RC-filter with 200R and 4.7µF.

http://sim.okawa-denshi.jp/en/CRtool.php

Gives us a -3dB frequency of 169 Hz and the graph to 10 kHz looks like this:

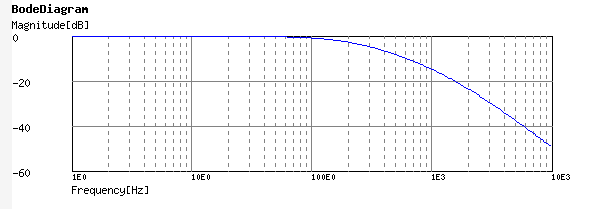

The new filter is a second-order filter with steeper rolloff.

http://sim.okawa-denshi.jp/en/CRCRtool.php

-3db freq is a bit worse with 589 Hz.

But higher frequencies are filtered much better because it is a second-order filter:

At 1 kHz it is about the same as the previous filter, above it becomes much better.

Since usually the slightly higher frequencies are what cause issues and not the stuff below 1 kHz, I think we also get an improved filtering with this change.

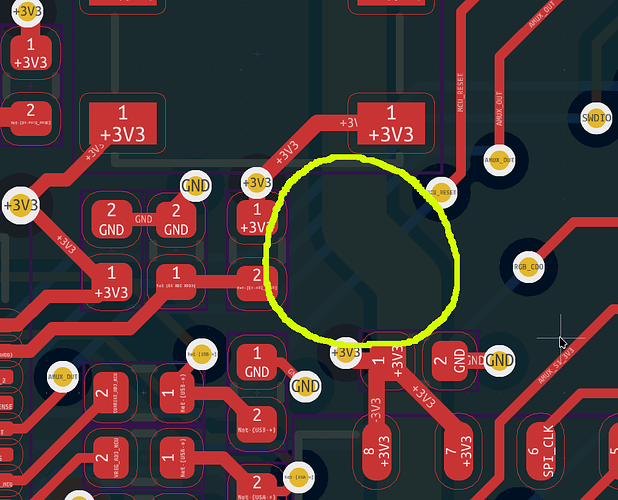

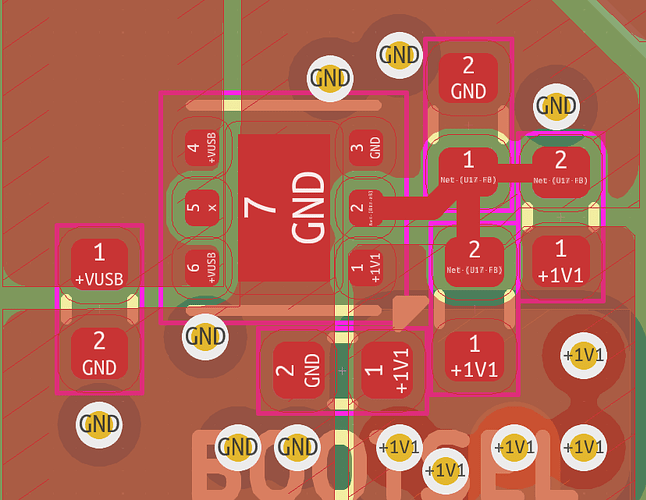

When I look at the layout I think there is space left for the two extra parts:

So this would be another change I suggest for 7Rev1. Then we can test if it is really an improvement or not.