Are you intending to sell this, or is this solely to help flash them in production?

If selling, are there that many folks who’d want/need to drop many devices into a programmer? (If it’s not as simple as dropping into a docking station, consider how this benefit the user vs. just using a Pico Debug Kit with a 3-pin milled pin connector.)

If very few to be sold, would selling it as a “kit” (e.g., “solder RP2040 Dev Board X here”) avoid the need for FCC/CE testing?

Other thoughts on reducing steps / improved experience

If this is intended for average developer folks, it would be beneficial to be “one step” / “one motion” to insert and use, which means it would likely need the debugger integrated. However, if I understand correctly, the debug / POGO pins cannot provide power. Thus, there is a need to plug in USB-C for power (even if not using it for data).

The USB-C connection is orthogonal to the plane for the debug pins. This makes it much more complex to have a single, linear motion for an encased BusPirate that will connect both the USB-C connector AND the debug pins. However, that’s the goal, as the best experience would be where the user leave the cables connected to the dock, and only inserts/removes the bus pirate.

If the BP boards were revised to have the debug port on the same side as the USB-C connector, a dock would be fairly easy to make, and a single motion would easily connect everything. But, that needs both a board and case revision … not a great option, and it wouldn’t support any existing boards / cases.

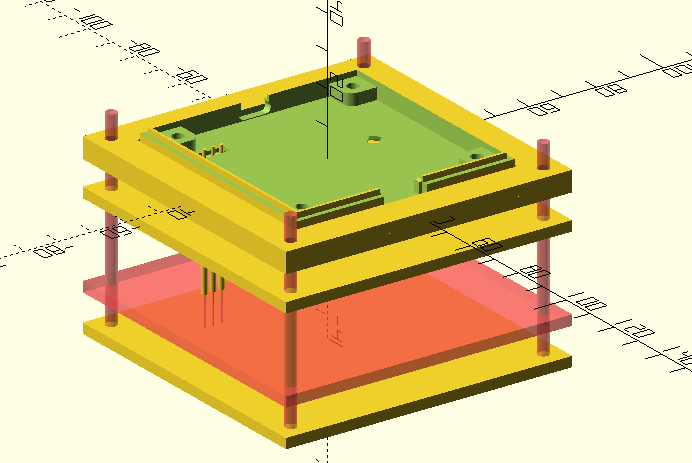

Slightly more complex, I can imagine a docking station style solution, where the POGO pins will drag along the back side of the case slightly until they “click” into place. This requires moving parts:

- Imagine the Nintendo Switch’s docking station (simply because it has USB-C at the bottom), but of course narrower screen-to-back to match the BP5 case dimensions, and with sidewalls to help align the USB-C connector.

- During the last ~10mm of pressing the BP5 down into the docking station, the BP5 case engages a spring-loaded lever.

- The lever’s action causes the POGO PCB to be brought closer to the docking station.

- The POGO pins might initially make contact with the back of the case, in which case they would slide along the back until the case is fully inserted.

- The POGO pins eventually make contact with the debug connector.

- Removal: Requires the POGO pin shape to allow the POGO pins to detatch from the debug connector with sideways force… then sliding along the case until the lever action retracts them sufficiently.

A more complex action would move the POGO PCB in lockstep with the pushing-down, while simultaneously closing the gap between the PCB and BP5. This more complex action would remove all strain from the POGO connectors, but … requires some maths to design the level action correctly (well beyond my ken).

Not terribly complex, but definitely more likely to wear out the POGO pins more rapidly, depending on the lever’s motion … likely want the lever to cause little/no change in distance initially, and then bump up fairly rapidly near the end.

I’ve no mechanical training, so likely many things above might not work perfectly, or require unrealistic tolerances, etc. Just some thoughts that start with the improved experience that makes it helpful to the random developer, then working backwards towards how that might be done.