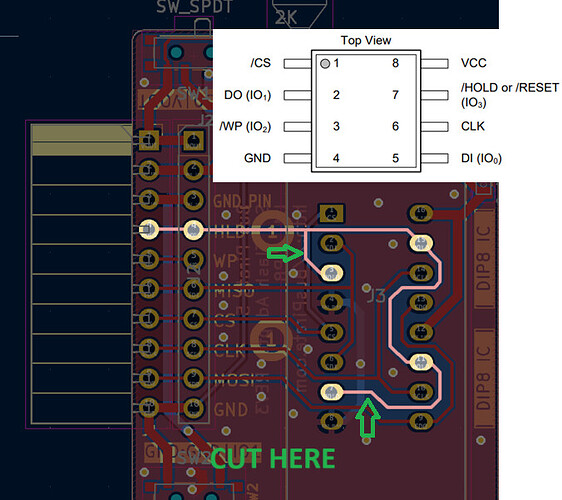

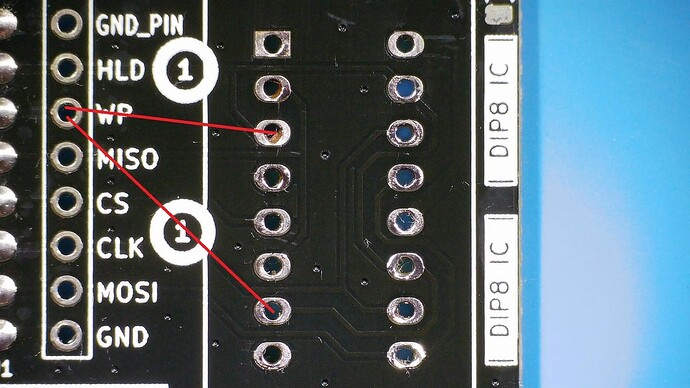

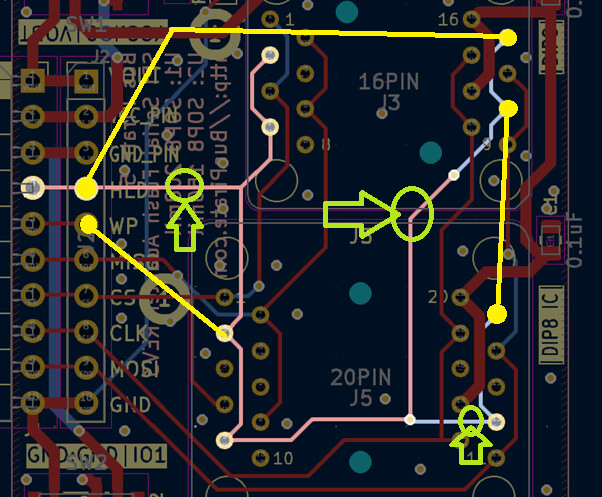

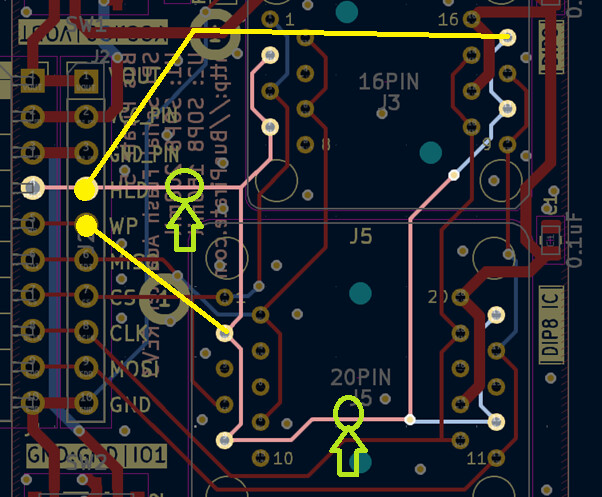

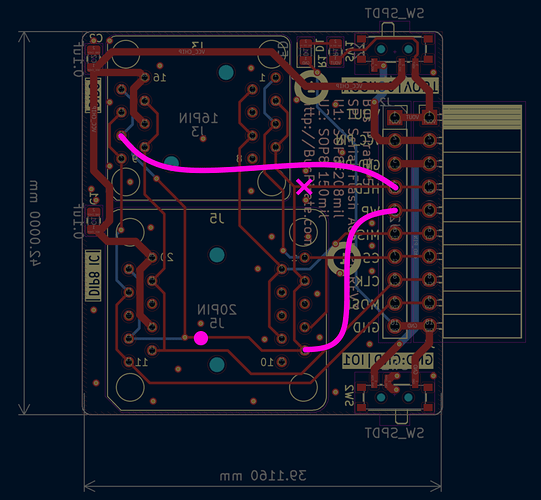

The user @b4shful reports a bug in the routing (2025-05-28) (HOLD BIO is connected to ZIF WP+HOLD, and WP BIO is disconnected from the ZIF).

As a way to procrastinate instead of doing the documentation (@Ian, I’ll try to do it today), here’s a little tutorial:

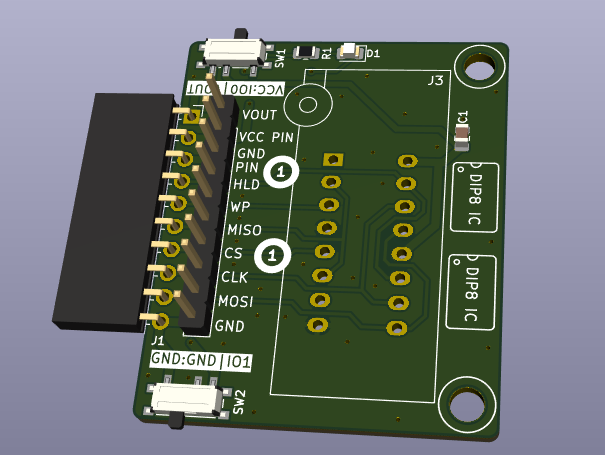

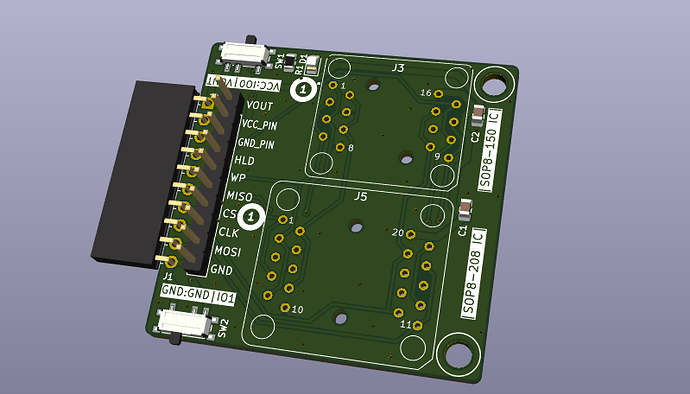

![]() First of all: Only do this fix if you’re interested in being able to control WP and HOLD separately; for some users, it might not matter.

First of all: Only do this fix if you’re interested in being able to control WP and HOLD separately; for some users, it might not matter.

We just need to make two cuts:

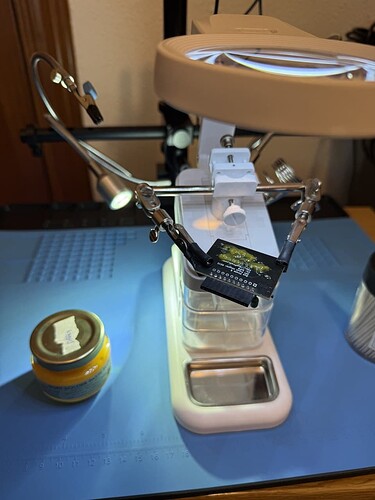

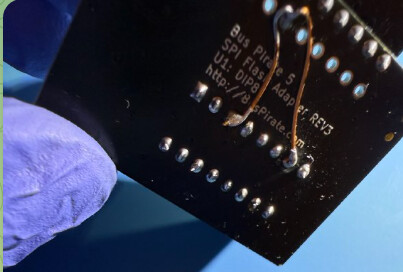

But first, you need to desolder the ZIF socket. Here’s a video “crap-tutorial” by me:

Here are some easy-to-follow steps (I hope):

Add leaded or low-temp solder to each pin.

Add solder paste to the pins:

Using tweezers and a hot air gun (I am using 380-400°C), desolder the ZIF socket:

Be patient and don’t pull hard; move the heat gun so that the heat reaches all the pins evenly.

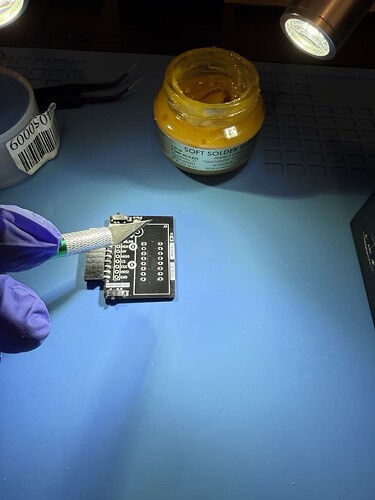

Remove the old solder from the pins using solder wick and flux (You can also use a hot and fine soldering tip—0.5 mm or smaller—and one of those manual solder suckers):

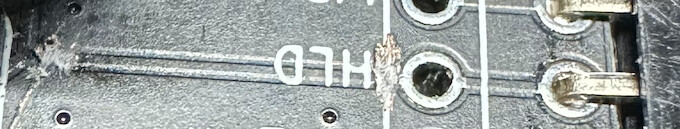

Cut the tracks!

I need to buy new blades; this is slipping and not cutting anything—it’s turned out a bit of a botch job.

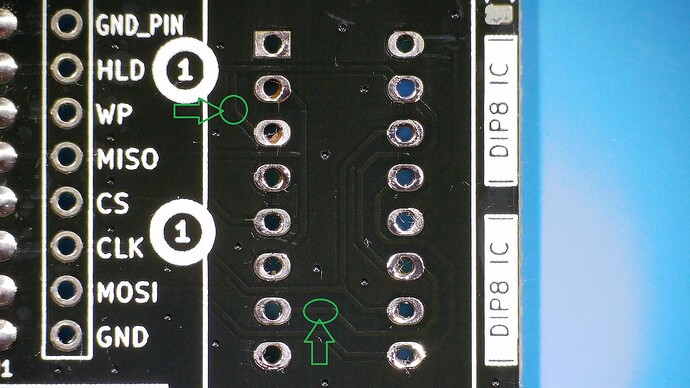

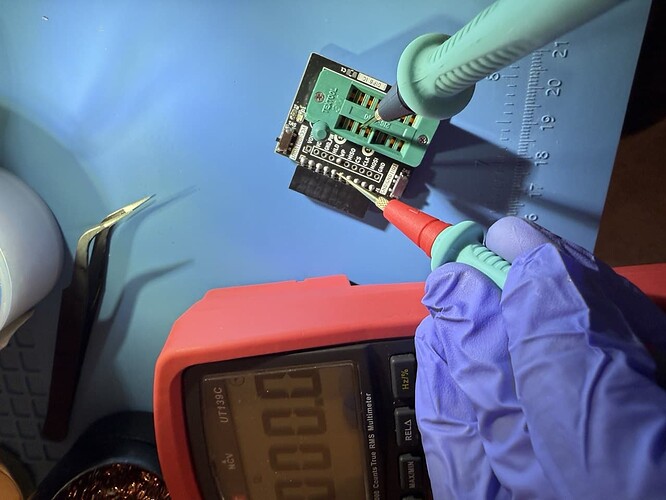

Make sure, using the multimeter in continuity mode, that HOLD and WP are no longer connected to each other.

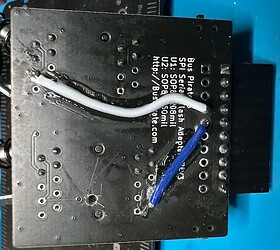

Resolder the ZIF and connect the WP pin to its proper location.

This turned out awful and it’s embarrassing for so many reasons haha, but I’m in a hurry:

Make sure with the multimeter that there’s continuity from the WP BIO pin to the ZIF.

Done!

NOTE: I did it quickly and made it easy for a novice to follow without cutting anything nearby… I didn’t design it with much regard for preserving signal integrity (@electronic_eel hates me for this haha)