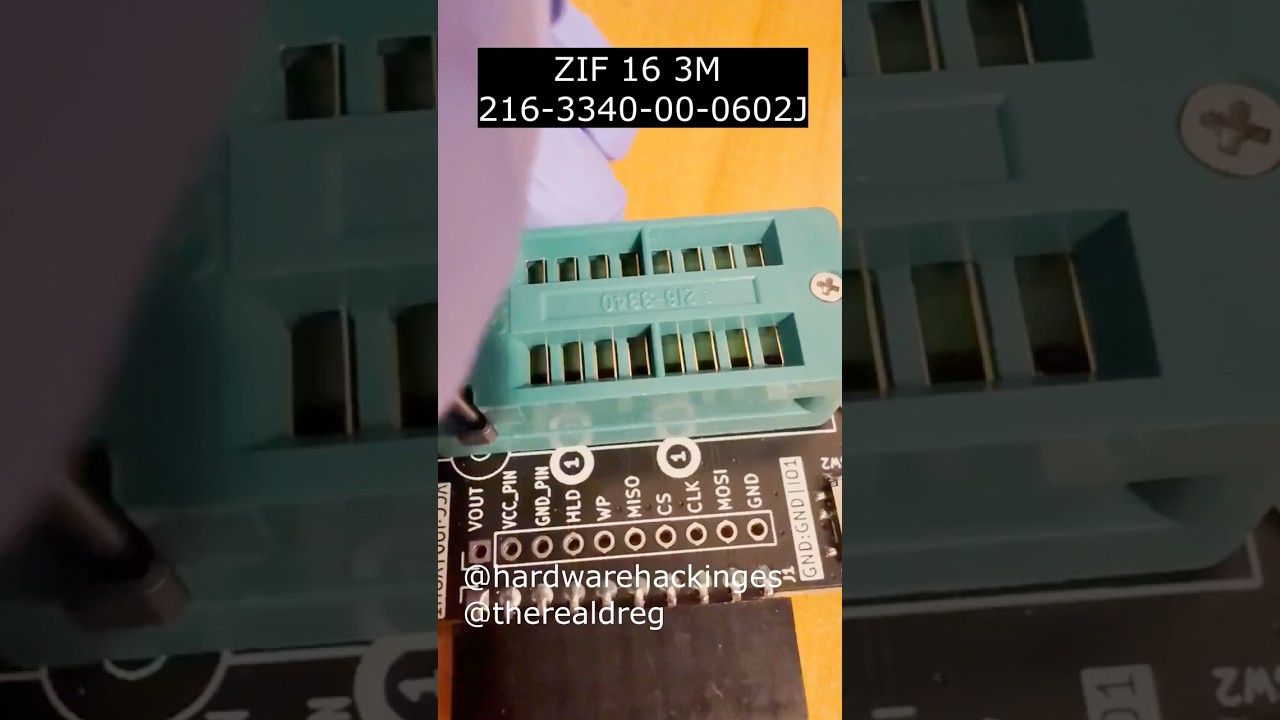

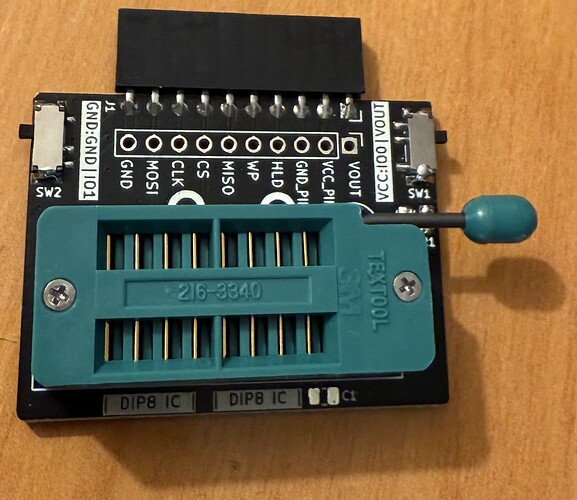

Replacing ZIF, premium ZIF socket ZIF 3M 216-3340-00-0602J Beryllium Copper (~25$)

thats alot of work. chipquik solder alloy and pull it off no problems. low melt solder alloy, i use it all the time to pull of chips and recently just fixed my reveltronics programmer dip48. just a thought.

The idea of the video is to show different ways to do the same thing using various tools and techniques, so anyone can do it based on the tools/skills they have.

ah gotcha, i guess i misunderstood. still cool way to improve your skills soldering ![]()

What temperature were you running with the wick “pool of solder” technique? I’ve never done it that way, but it looks really useful.

Thanks for sharing the video - really good stuff!

Unless I’m working on something very delicate, I prefer using old-school JBC soldering irons without temperature regulation.

For less delicate SMD work, I usually use the JBC 14-ST with the 0.5mm fine tips.

For MY solder pool method (quite a waste, by the way ![]() ), I use a classic JBC 30-ST with the R-10D tip:

), I use a classic JBC 30-ST with the R-10D tip:

Power

25W

Max. temperature

380 ºC

Time to reach 300ºC

2min 15s

Solder: MBO 60/40

Btw, I have several JBC 30-ST and several JBC 14-ST—if I need more heat, I use multiple at the same time with both hands.

Thanks! I have some old scrap boards, I’ll have to give it a try. It’s always good to learn new ways to do things.

I came up with this method because I’ve seen videos where people use enameled copper wire, but… it’s more likely that anyone would have desoldering wick, even if it’s a cheap one, right? ![]()

Exactly! I was thinking I’d try it with the cheap stuff I don’t use for anything else.

Be patient, heat everything thoroughly for a while, and make sure all the pins have solder on both sides… It takes a bit of time to melt everything properly.

i was wondering why I was unfamiliar with the jbc tool you were mentioning seems that is their classic pencil line, europe only power. Looks similar to american beauty/edsyn/ersa soldering stations. I always think its interesting to see how everyone else works, if you aren’t soldering in a cell phone/laptop store or for a job, you dont really solder next to people to learn. cheers.

CCC events and its workshops can be a godsend on that part, too. at Easterhegg last year there was one about PCB rework, too.