For the negative voltages I first played with -0.5V to -1V and -5V. No real differences there - some contact chatter and the protection reacting.

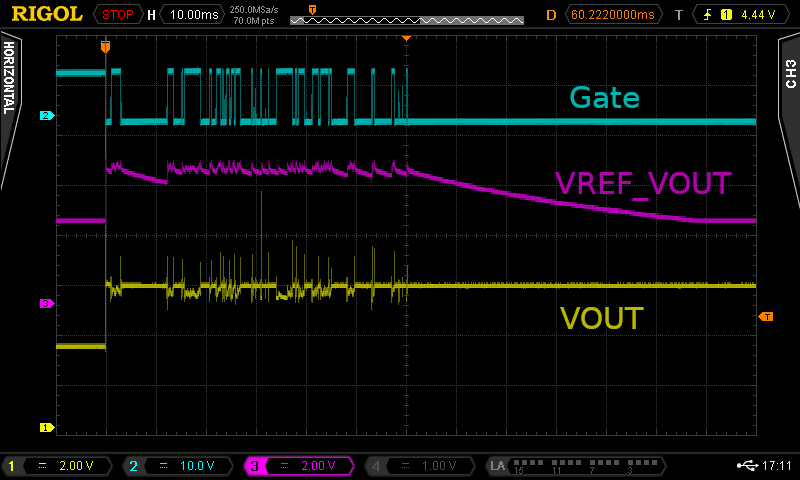

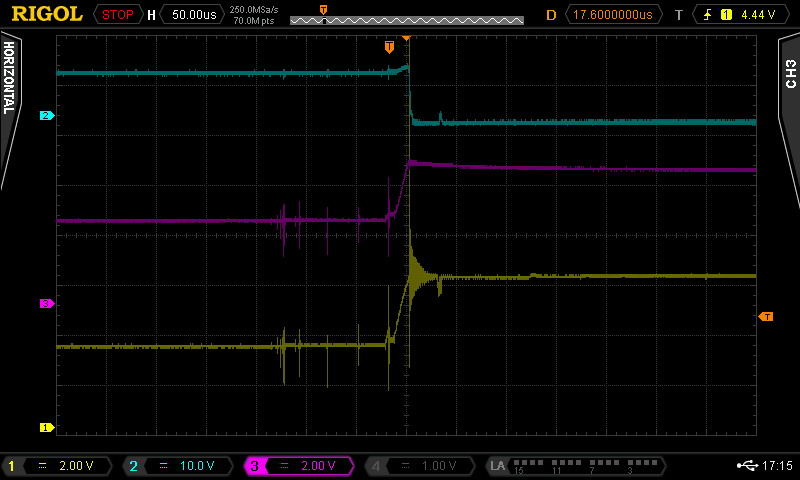

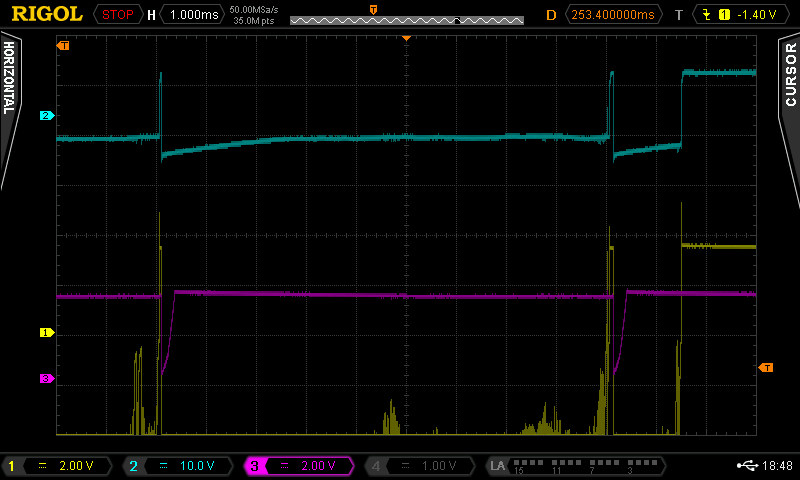

Here for example -5V:

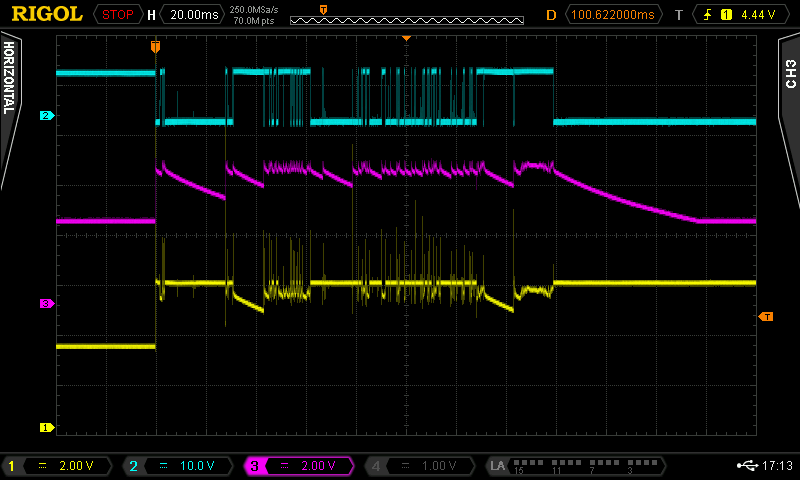

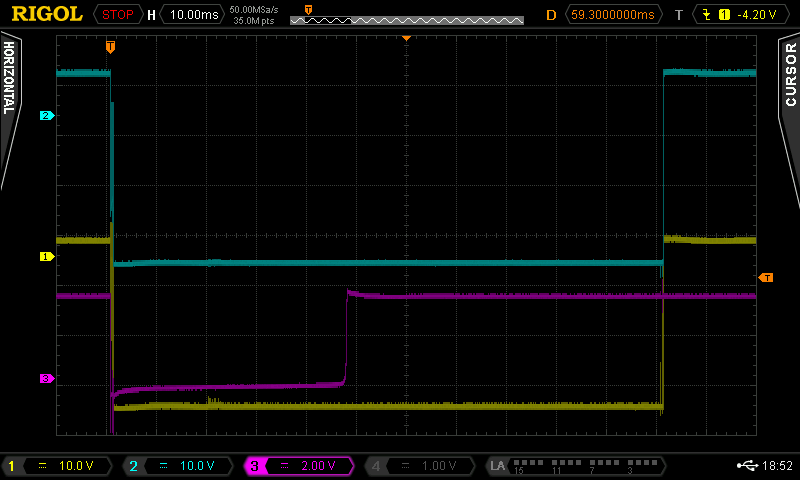

And zoomed in to the contact chatter:

As you can see the VREF_VOUT never ever even goes slightly negative - perfect.

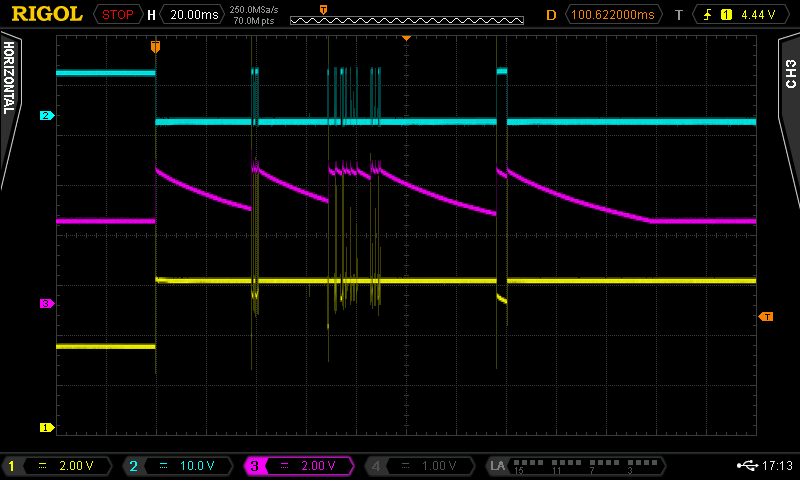

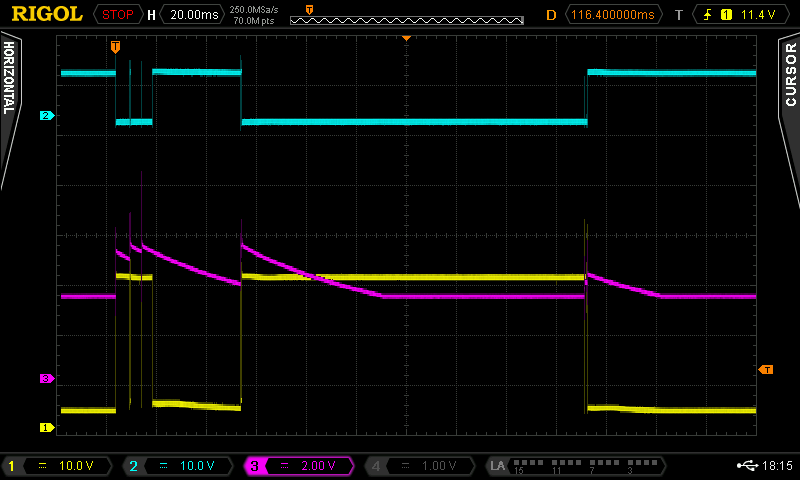

Now I got out the “big guns” and connected my 470µF low-esr polymer cap again. Connected to the lab PSU at 30V and wired up for negative voltages, then touching the leg of the cap to VOUT looks like this:

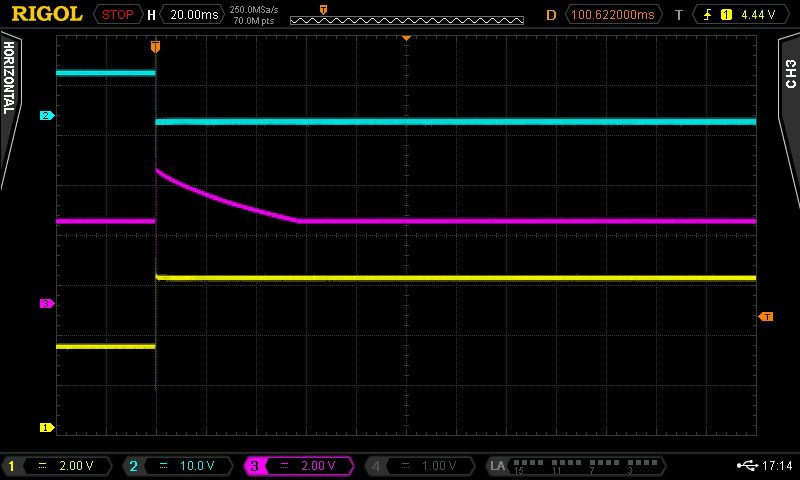

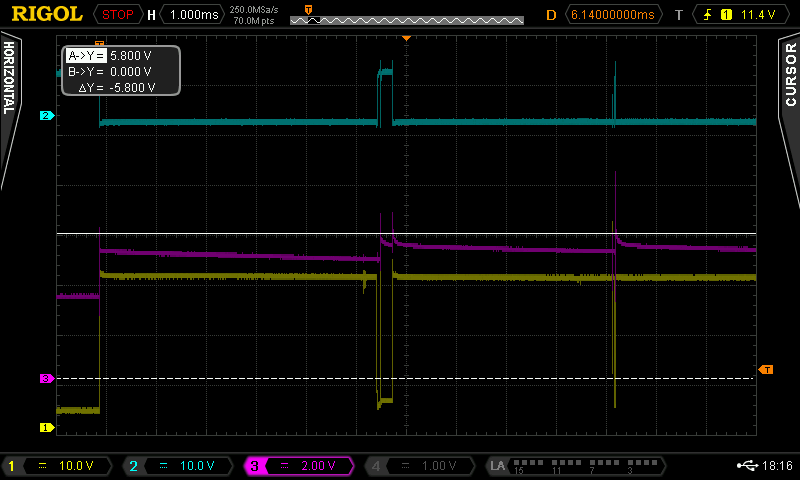

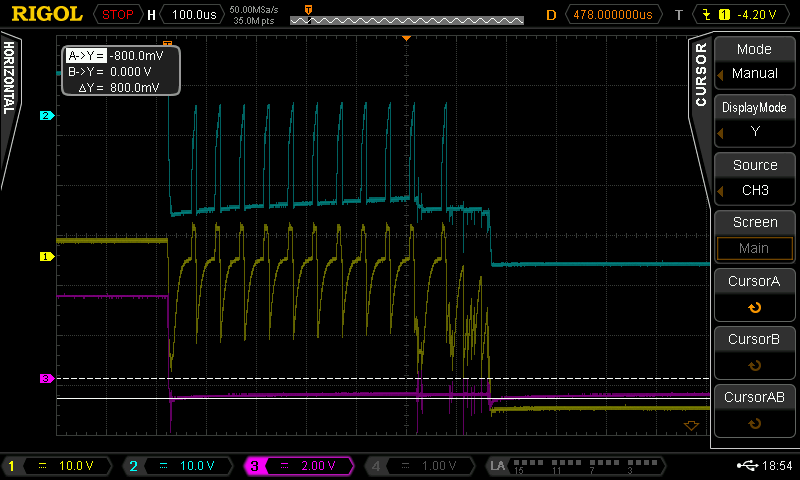

Zoomed in to the first contact:

I saw a bigger spark fly when touching the cap.

Now this is more interesting to analyze!

Let’s start with the non-zoomed version first. On the big scale the circuit reacts as designed. VOUT_VREF is hooked up to the voltage regulator, configured to 3.3V. It looks like it’s regulation circuit gets “shocked” a bit and it takes some time to recover and enable the 3.3V out again.

On the zoomed in version the most important thing is how low VOUT_VREF goes. -800mV is not perfect, but this was the most stressful test for the whole circuit. A bit less would be better, but I guess the components will survive. I think the SMF5.0A TVS-diode is the one that limits this voltage first before the gate voltage drops and the mosfets close.

Then we have this oscillation phase going on for about 600µs. My guess is that the capacitor gets discharged quickly, due to the TVS activating. You can see in the yellow trace (VOUT) that the voltage rises from nearly -30V to about 0V. The protection then disengages, the gate voltage rises. Then VOUT falls again and the cycle repeats. I guess this is the regulation circuit of my lab PSU reacting. Also the negative supply voltage and it’s capacitors of the comparator has to be discharged.

All this could be amplified by contact chatter: as I touch the leg of the cap to the VOUT pin there is no stable electric contact. So we have some contact resistance. As I see quite a spark, small particles vaporize and we get a higher contact resistance. This allows the PSU to charge the cap again without hitting the current limit.

Once the physical contact is stable after like 600µs the situation stabilizes.

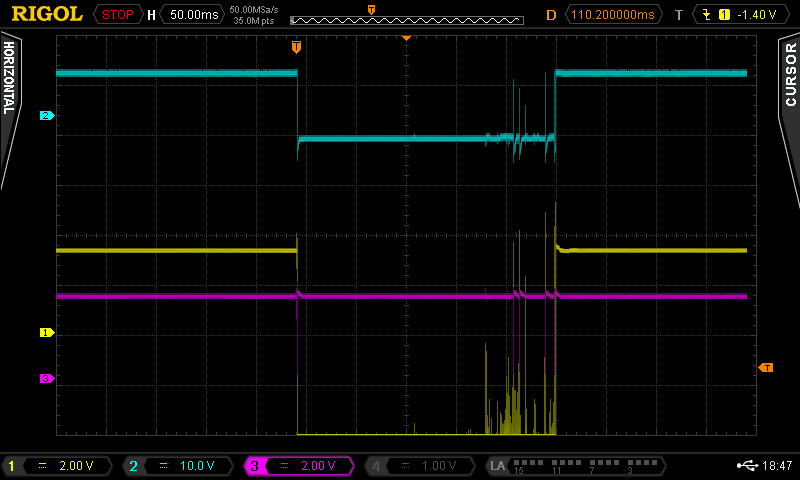

I repeated this like 50 times in short and longer succession, with different current settings on the lab psu and so on. Apart from the sparks I did not see any adverse effects, the circuit survived.

So I’d consider this test passed too.

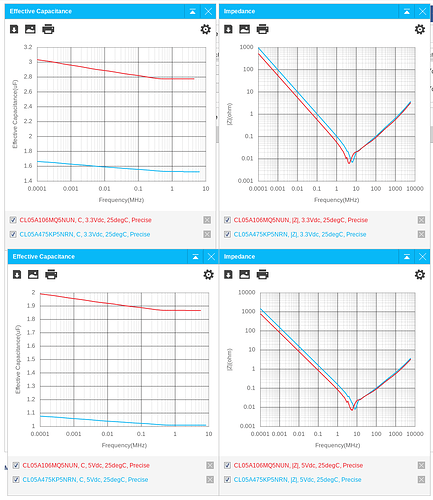

![]() This seems less and less common though, laptops especially have much more consistent 5V rails.

This seems less and less common though, laptops especially have much more consistent 5V rails.